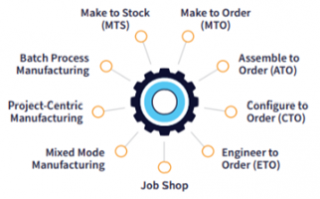

Types of Manufacturing Suited for Acumatica

Every manufacturer has a different way of creating its products. Acumatica’s Manufacturing Edition can support many different types of production methods. Below finds a list of the types of production methods that Acumatica supports.

ASSEMBLE TO ORDER (ATO)

ATO manufacturers assemble components to fulfill customer orders. ATO companies rarely stock finished assemblies. They have simple processes and production requirements.

- Demand Forecasting

- Kitting and Disassembly

- Light Manufacturing

CONFIGURE TO ORDER (CTO)

CTO manufacturing generates unique finished goods using a rules-based product configurator to define the bill of materials and routing based on options and values such as color, size, or other variables.

- Product Configurator

- B2B or B2C Commerce

- Matrix Items

REMANUFACTURING (REMAN)

Remanufacturing relates to “cores” or worn parts repaired for resale. Remanufacturing is common for transmissions, batteries, furniture, toner, and other products. Recycling and disassembly are a form of remanufacturing where products are broken down into salvageable components.

- Disassembly

- By-products and Co-products

- Core Management

ENGINEER TO ORDER (ETO)

ETO manufacturers design products based on customer specifications. Assemblies and raw materials are stocked, but they are not assembled until a customer order is received, and the part is designed by engineering.

- Engineering Change Orders

- Vendor Request for Quote

- CAD Bill of Material Integration

MIXED MODE (MM)

Mixed-mode manufacturers produce finished goods both to stock (MTS) and to order (MTO). Also, companies that operate discrete and process operations are sometimes called mixed mode.

- Demand Forecasting

- Engineering Change Orders

- Bill of Materials and Recipes or Formulas

JOB SHOP

Job shops have minimal raw materials and finished goods inventory. Most orders begin with an estimate. Job shops purchase materials directly for customer orders. True job shops do not stock finished goods. Job shops ship directly from work in process to the customer.

- Estimating

- Vendor request for quote (RFQ)

- Job Costing

MAKE TO STOCK (MTS)

MTS is a manufacturing philosophy where finished goods are produced to stock. Existing stock fulfills customer orders as opposed to fulfillment from manufacturing. Manufacturing proactively maintains adequate stock levels for forecasted customer orders.

- Demand Forecasting

- Inventory Replenishment

- Engineering Change Orders

- B2B or B2C Commerce

MAKE TO ORDER (MTO)

MTO manufacturers rarely stock finished goods. Instead, manufacturing is scheduled to fulfill direct customer orders. Variants of MTO manufacturing include ATO, CTO, ETO, and Job Shop manufacturing.

- Estimating

- Vendor Request for Quote (RFQ)

- CAD Bill of Material Integration

- Job Costing

- Product Configurator

If you are interested in learning about one of these manufacturing methods in more depth, please reach out to Polaris Business Solutions. We would love to show you a full demonstration of Acumatica and its full benefits. Please email info@polaris-business.com.